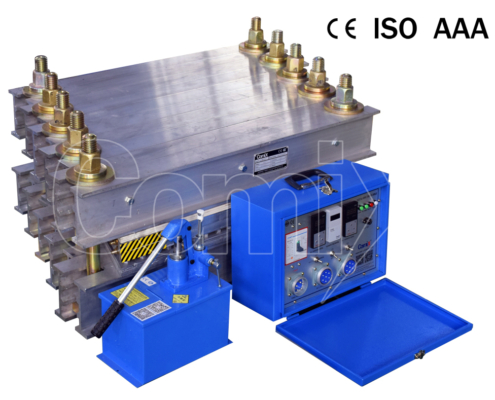

Conveyor Belt Vulcanizing Machine

Production Description

Conveyor Belt Vulcanizing Machine are mainly applied to industries for splicing and repairing for conveyor belting such as construction material cement, metallurgy, mine, chemical industry ,tobacco, power plant, port, dock, and food automatic line field.

The machine is made of aluminum alloy, small volume and light weight, three-phase source of power supply. The temperature of the heating plate is uniform. Water pressure system can supply stable pressure. The vulcanizing machine is also equipped with auto electric control, it is easy to operate. Fast heating, steady heating temperature.

When order (please supply below information, our engineer will make a solution for you)

- What kind of belt, light duty belts or heavy duty belts

- Max belt width

- Heating platen length (or please supply belt manufacturer’s recommended splice length)

- Working Voltage

- Pressure requirements

- Degree of heating platen (standard will be 20 degree)

Technical Parameters

| Voltage | 220V 380V 415V 660V 50HZ(Other voltages are also available) |

| Fast cooling time | About 30minutes (from 145 degrees down to 70 degrees or less) |

| Temperature raise (from normal temperature to 145℃) | About 35 minutes |

| The temperature difference of heating plate working surface | ±2°c |

| Temperature adjustment range | 0~200°c |

| Vulcanizing pressure | 0.7~1.4 MPa(100PSI~200PSI) |

| Time of heat preservation | Usually 30mins |

| Degree of heating plate | 16°,16.7°, 20°, 22°(or other degrees) |

| Suitable for belt type | Common rubber conveyor belt and steel cord conveyor belt |

Specification

| Model | Belt Width | Platen Size(20◦) | Splice Length | Qt. Bolts | ||||||

| A | B | 100PSI (0.7MPa) | 200PSI (1.4MPa) | |||||||

| in | mm | in | mm | in | mm | in | mm | sets | ||

| 3431 | 24-25 | 650 | 34 | 880 | 31 | 800 | 28 | 730 | 8 | 10 |

| 4131 | 24-25 | 650 | 41 | 1060 | 31 | 800 | 35 | 910 | 10 | 12 |

| 3439 | 30-31 | 800 | 34 | 880 | 39 | 995 | 28 | 730 | 8 | 10 |

| 4139 | 30-31 | 800 | 41 | 1060 | 39 | 995 | 35 | 910 | 10 | 12 |

| 3448 | 36-39 | 1000 | 34 | 880 | 48 | 1228 | 28 | 730 | 8 | 10 |

| 4148 | 36-39 | 1000 | 41 | 1060 | 48 | 1228 | 35 | 910 | 10 | 12 |

| 3456 | 42-47 | 1200 | 34 | 880 | 56 | 1430 | 28 | 730 | 8 | 10 |

| 4156 | 42-47 | 1200 | 41 | 1060 | 56 | 1430 | 35 | 910 | 10 | 12 |

| 3458 | 48-51 | 1300 | 34 | 880 | 58 | 1490 | 28 | 730 | 8 | 10 |

| 4158 | 48-51 | 1300 | 41 | 1060 | 58 | 1490 | 35 | 910 | 10 | 12 |

| 3465 | 54-55 | 1400 | 34 | 880 | 65 | 1650 | 28 | 730 | 8 | 10 |

| 4165 | 54-55 | 1400 | 41 | 1060 | 65 | 1650 | 35 | 910 | 10 | 12 |

| 3467 | 59-60 | 1500 | 34 | 880 | 67 | 1700 | 28 | 730 | 8 | 10 |

| 4167 | 59-60 | 1500 | 41 | 1060 | 67 | 1700 | 35 | 910 | 10 | 12 |

| 3473 | 61-63 | 1600 | 34 | 880 | 73 | 1867 | 28 | 730 | 8 | 10 |

| 4173 | 61-63 | 1600 | 41 | 1060 | 73 | 1867 | 35 | 910 | 10 | 12 |

| 3482 | 70-72 | 1800 | 34 | 880 | 82 | 2080 | 28 | 730 | 8 | 10 |

| 4182 | 70-72 | 1800 | 41 | 1060 | 82 | 2080 | 35 | 910 | 10 | 12 |

| 3490 | 78-80 | 2000 | 34 | 880 | 90 | 2300 | 28 | 730 | 8 | 10 |

| 4190 | 78-80 | 2000 | 41 | 1060 | 90 | 2300 | 35 | 910 | 10 | 12 |

| 3497 | 84-86 | 2200 | 34 | 880 | 97 | 2480 | 28 | 730 | 8 | 10 |

| 4197 | 84-86 | 2200 | 41 | 1060 | 97 | 2480 | 35 | 910 | 10 | 12 |

FAQ

01) Q: Do you have any certificates for the vulcanizing machine?

A: We have CE Certificate and ISO9001:2015 for the machine.

02) Q: Normal delivery time?

A: About 20 working days. Customized machines will take a bit longer.

03) Q: Will you test the machine before shipping?

A: Yes, each machine, we will install and test before shipping.

04) Q: What after-sales service will you supply?

A: If the problems arising from the our manufacturing defects in the guarantee period, we will provide full support to solve the problem, reducing the loss. At the same time, we will provide the free spare parts; Over the guarantee period,if you want to replace the accessory, we can give some discount on the price.

05) Q: Whether can visit your workshop to see how to process the machine?

A: No problems, you are always welcomed to visit us.

06) Q: Can I be your agent in our area?

A: Yes. ComiX is looking for the agents all over the world. If you are interested , please feel free to contact us to negotiate the agency mattes in details.