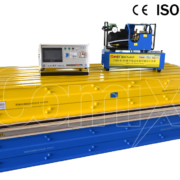

ALEX-TC3 Touch Screen Computer Temperature Control System Ultra-light Vulcanizing Machine

ALEX-TC3 touch screen computer temperature control system ultra-light vulcanizing machine characteristics:

- Equipped with computer touch screen temperature control technology, using ComiX® software programming system, Japanese Panasonic, Fuji and other imported electrical core parts assembly, can choose between “water pressure, air pressure, and oil pressure” to switch pressure, heating plate weight is about 30%-65% lighter than the old vulcanizing press , and the cooling speed is about 80% faster than that of the old vulcanizing press.

- The core components of the ultra-light vulcanizer adopt “ComiX”brand heating blanket + “ComiX” brand pure rubber pressure bag( can use wateror airpressure) , equipped with electric air pumps or water pumps; the latest invention patents are ultra-light and fast water cooling aluminum alloy heating plate takes only 5 to 8 minutes to cool down the vulcanizing temperature. It completely eliminates the traditional old-fashioned built-in cooling copper pipe cooling process that is easy to leak water and electricity decades ago! The heating plate is close to the belt, and the bonding surface can cool down the high temperature inside the tape 100% super quickly, and the temperature cooling is super fast!

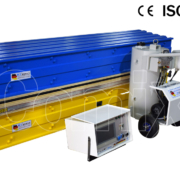

Description of ultra-light conveyor belt vulcanizer with ALEX-TC4 touch screen computer temperature control system:

- It has 2 characteristics of ALEX-TC3 computer touch screentemperature cabinetat the same time;

- The computertemperature cabinetadopts industrial + Internet technology, big data wired or wireless collection, has a touch screen for joint control and monitoring, supports mobile phone remote control, heating up, keeping warm, cooling down, pressurizing, maintaining, and relieving pressure. The working interface supports the curve display function, and can be controlled by multiple online IoT technology with one key. It can use the remote collection of big data and the external plug-in “USB” socket to collect and analyze data such as temperature, current, and power. It also uses GPS and Beidou dual systems to locate the vulcanizer globally, which is suitable for group company leaders to sit in the office for remote command and real-time monitoring.

- The intelligent control system and portable control instrument can simultaneously monitor the temperature and pressure curve changes of multiple sets of ultra-light conveyor belt vulcanizers at the same time, remotely heating switch control, pressure control, timing switch control, temperature reminder, conveyor beltjoint history record preservation, predict vulcanized joints, and has the functions of automatic temperature control, automatic pressure control, automatic protection, and automatic detection. You can also remotely modify and adjust the vulcanization temperature, pressure, heat preservation time, etc., on the computer touch screen or mobile phone. The heat preservation time is automatically timed, and the time is automatically stopped, and there is a reminder signal or indicator light display, which accurately and automatically completes the belt joint “heating, keeping temperature, and cooling “work process

Specifications of ALEX ultra light conveyor belt vulcanizer with touch screen temperature cabinet |

||||

| Model Number | Belt Width(mm) | Heating Plate Size (B*A)(mm) | Power(KW) | Bias Angle |

| ALEX-DN2832 | 650 | 820×710 | 8 | 20° |

| ALEX-DN2839 | 800 | 995×710 | 9 | |

| ALEX-DN3439 | 995×880 | 11 | ||

| ALEX-DN2848 | 1000 | 1228×710 | 11 | |

| ALEX-DN3448 | 1228×880 | 13 | ||

| ALEX-DN4148 | 1228*1060 | 15 | ||

| ALEX-DN3456 | 1200 | 1430×880 | 16 | |

| ALEX-DN4156 | 1430×1060 | 19 | ||

| ALEX-DN3465 | 1400 | 1650×880 | 17 | |

| ALEX-DN4165 | 1650×1060 | 21 | ||

| ALEX-DN3473 | 1600 | 1867×880 | 22 | |

| ALEX-DN4173 | 1867×1060 | 25 | ||

| ALEX-DN3481 | 1800 | 2079×880 | 23 | |

| ALEX-DN4181 | 2079×1060 | 27 | ||

| ALEX-DN3490 | 2000 | 2300×880 | 25 | |

| ALEX-DN4190 | 2300×1060 | 30 | ||

| ALEX-DN3497 | 2200 | 2478×880 | 27 | |

| ALEX-DN4197 | 2478×1060 | 32 | ||