Possible Causes and Solutions for Bubbles in Belt Splices

The appearance of bubbles in belt splices (especially rubber conveyor belt splices) can severely compromise joint strength and durability. Below are potential causes and corresponding solutions:

I. Vulcanization Process Issues

1. Insufficient Vulcanization Temperature

– Cause: Temperature does not meet vulcanization requirements (typically 145-155℃)

– Manifestation: Incomplete vulcanization of internal rubber

– Solution: Calibrate the vulcanizer’s temperature sensor to ensure proper temperature

2. Insufficient Vulcanization Time

– Cause: Vulcanization time is shorter than material requirements

– Manifestation: Surface appears vulcanized, but internal bubbles remain

– Solution: Adjust vulcanization time based on belt thickness

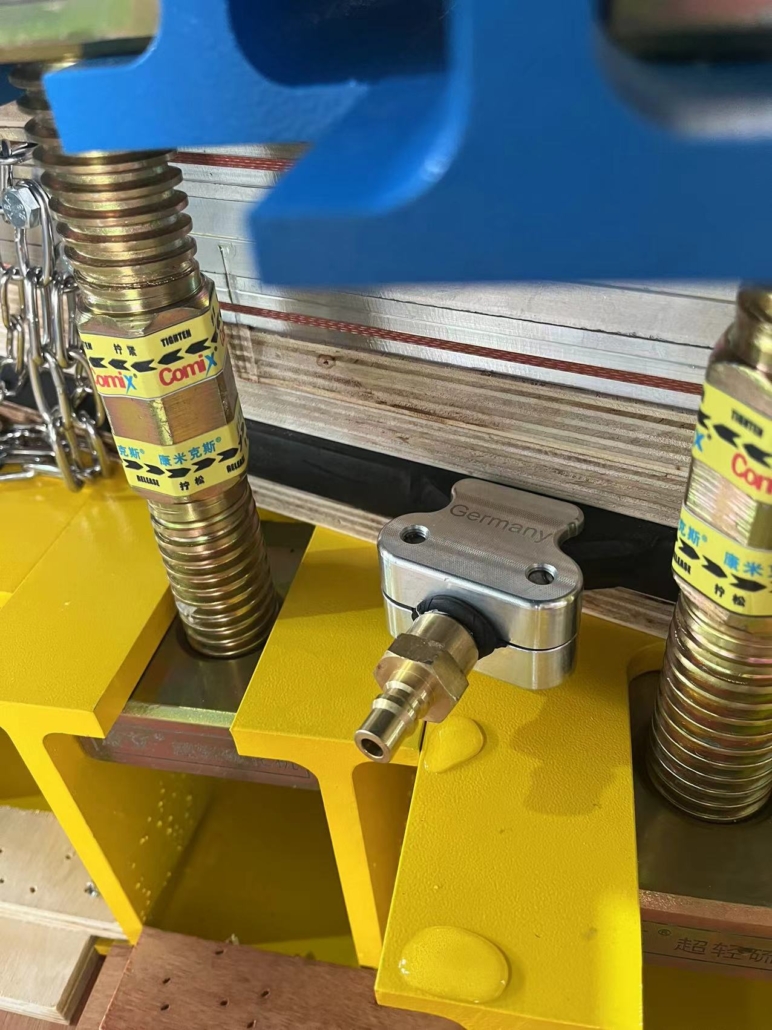

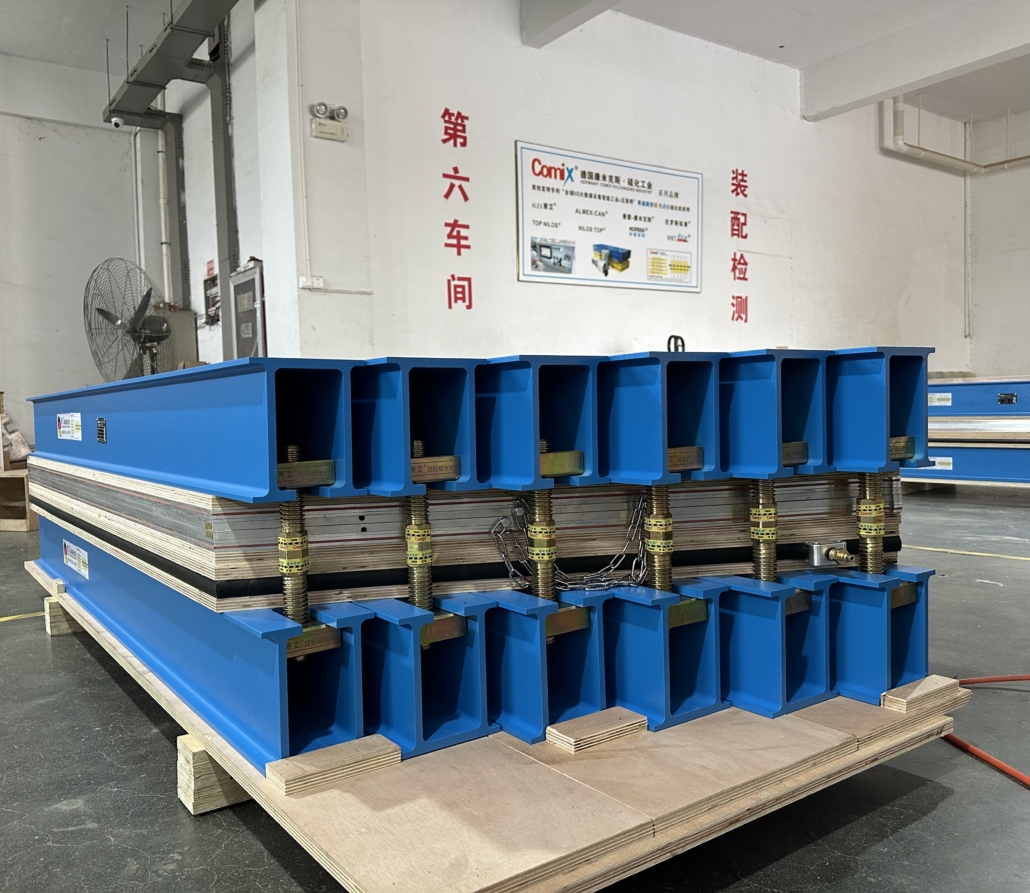

3. Unstable Pressure

– Cause: Insufficient or fluctuating vulcanizer pressure

– Manifestation: Irregular bubble distribution

– Solution: Inspect the pressure system to maintain consistent pressure

II. Material Handling Issues

1. Moisture in Rubber Compound

– Cause: Unsealed rubber compound absorbs moisture

– Manifestation: Steam bubbles form during vulcanization

– Solution: Pre-bake rubber compound before use (60°C × 4 hours)

2. Insufficient Solvent Evaporation

– Cause: Premature mold closing after adhesive application

– Manifestation: Small bubbles concentrated at the bonding surface

– Solution: Ensure complete solvent evaporation (air-dry for 20-30 minutes)

3. Excessive Adhesive Thickness

– Cause: Single adhesive layer exceeds 0.8mm

– Manifestation: Layered bubbles

– Solution: Use “thin-layer, multiple-coat” technique (each layer ≤ 0.3mm)

III. Operational Issues

1. Residual Grinding Dust

– Cause: Incomplete cleaning of rubber debris after grinding

– Manifestation: Linear bubbles at the interface

– Solution: Thoroughly clean with a dedicated cleaner and wire brush

2. Uneven Overlapping

– Cause: Misalignment in step-type splicing

– Manifestation: Localized large bubbles

– Solution: Use positioning fixtures to ensure precise alignment

3. Incomplete Air Removal

– Cause: Insufficient air venting before vulcanization

– Manifestation: Scattered small bubbles

– Solution: Apply the “three-press, three-release” method (pressure → depressurization cycle)

IV. Environmental Factors

1. High-Humidity Conditions

– Cause: Construction in environments with >80% humidity

– Manifestation: Honeycomb-like micro-bubbles

– Solution: Set up temporary moisture-proof shelters and use dehumidifiers

2. Low-Temperature Work

– Cause: Rubber compound activity decreases at <10°C

– Manifestation: Edge bubbles

– Solution: Preheat the belt to ≥25°C before splicing

V. Quality Inspection & Repair

1. Bubble Detection Methods

– Tap Test: Lightly tap with a wooden mallet to detect hollow sounds

– Ultrasonic Testing: Professional scanning equipment

– Cross-Section Inspection: Cut a sample section for observation

2. Repair Solutions

– Small Bubbles (<3mm): Drill and inject adhesive, then perform localized re-vulcanization

– Large Bubbles: Cut out the defective section and re-splice

– Full-Section Bubbles: Must redo the entire splice

Prevention Recommendations:

– Establish a process card for splices, recording temperature/pressure/time curves for each vulcanization to facilitate troubleshooting.

– Key operators should be certified and undergo periodic skill assessments.